The following guest post and images were contributed by Daniel Appel. He contacted me about a review he had written for the yet to be released ROSCH Works SLM2. I enjoyed reading the rationale and background on how he arrived at this weaponlight solution so I agreed to publish it.

Daniel Appel is a former United States Marine, spending six years as a Crytologic Linguist (Arabic, Pashto) and SIGINT Support Team Leader. He is currently pursuing a Masters of Engineering in Systems Engineering, and works as an Aerospace Machinist and Software Developer. He has been active in the shooting sports since 2003, and also enjoys mountain biking and playing with Scottish Highland Bagpipe bands.

Rosch Works SLM2 and Surefire KM1 LED Head: Does this setup do it all?

When I first encountered the Rosch Works SL1 line of integrated weaponlight/front sight setups, I was very curious to see if I had finally found the lightweight and affordable solution I had been seeking for my compact handguard carbines.

On lightweight rails the majority of default real estate is available on the 12:00 top side (e.g. BCM KMR, KAC URX-4, Troy Alpha, DD SLiM, Centurion CMR, etc.). When it comes to making efficient use of that space while keeping the complete weapon system svelte, the Rosch Works SL’s are arguably the best possible solution, which is why it’s unsurprising to me that guys like Mike Pannone have been running the Rosch Works offerings for over a year now.

To further understand why the SL1 concept was so intriguing to me, I’ll explain a bit about my weapon mounted light and irons sights preference I bring to this review. My preferred setup is influenced very heavily by Larry Vickers and others who prefer the ambidextrous and rugged capability of Surefire (or similar) weaponlights mounted at 12:00 in conjunction with fixed iron sights or a fixed front sight post – for example the X300/X300U from Surefire mounted in front of a fixed front sight post or Daniel Defense 1.5 Fixed rail mounted front sight. For me this arrangement confers all the advantages of a constantly cowitnessed fixed front sight which also serves as an accidental light discharge mitigating tool for the X300 light mounted on the rail directly in front; my wife has adopted this exact setup for her pair of lightweight carbines.

On carbines I own with low powered variable optics, I wanted to retain that same inherently ambidextrous 12:00 mounting solution, but with the ability to run folding and/or offset iron sights. Furthermore, I have discovered through extensive experimentation that my preferred activation solution for weapon mounted lights is the Surefire Z68 tailcap (like Surefire Scout series lights). Again, the ability to press briefly and receive momentary light or push-through and have constant-on is quite desirable for me, and I prefer not to rely on remote switches if possible; so I’ve adopted running Surefire M300 and X600 scout lights, or VTAC L4 scout-like facsimile lights on non-offset aftermarket mounts at 12:00 as my answer for these rifles.

For even shorter handguards I was presented with a problem in the form of wanting to still run a 12:00 weapon mounted light with fixed iron sights and run this setup in front of a LDI DBAL-I2 also mounted at 12:00. This created a pressing need for a weaponlight that was compact and allowed for a fixed front sight. For what I wanted, the SL1 was almost the answer I wanted, but the SLM2 fits the niche as a truly ideal solution.

For the initial SL1 design, the benefits were undeniable: the very compact front-to-rear footprint possible with this setup was clearly desirable on shorter handguards, with a huge added bonus being the impressive weight savings. For these reasons alone, the SL1 is a truly remarkable light in it’s own right. If I was seeking a very affordable solution to a simple white LED WML and sight post space saver on a compact and/or lightweight carbine, I would be extremely happy with the existing SL1.

When I first went through this logical process, I contacted Don at Rosch Works, and asked if it was possible to perform a slight modification to the inside diameter of the existing SL1/SLM1 design to accommodate the Surefire Executive series of lights. What I specifically had in mind was running the exquisite Viking Tactics L4 Surefire lights (basically an E2D/E1B tube, Z68 Tailcap, and KX2/KX1 LED Scout Head). The initial answer was that of course it was possible, but Don immediately pointed out that I’d be basically crazy for wanting to do that, since the SL1 already does everything that light setup does with a higher output (250+ lumen torch) and lower cost (my complaints would likely be only related to the particular tailcap used on the Malkoff Devices light chosen for the SL1, and compatibility with Surefire Z68 and SR07 tailcaps).; but they’d start looking into trying to make the SLM2 (for SureFire executive series lights) setup anyway since it would allow use of the Surefire LED heads and integration with IR systems using existing remote switches like the Surefire SR-07-D-IT.

Once I got the go-ahead from Rosch that the SLM2 was a real possibility, I realized that I wanted something one step further: a White/IR capable weapon mounted light with integral front sight – even though this line of thinking was back in May 2014, I had a good enough understanding of Surefire product development timelines to make a reasonable assumption that eventually a KM1 LED Head (3V White/IR Scout Light Head from the then unannounced M300V Scout Light) would come out, and allow me to take a Surefire 3V Executive (E-1) body, install a Z68 Tailcap, and KM1 head and have myself a poor man’s M300V – an option not immediately available from Malkoff Devices.

This means that a Rosch SLM2 with the KM1-Vampire LED head becomes a truly one-of-a-kind triple threat bolt on part: a fixed front sight which houses a white/IR weaponlight. Not only is it the most compact and lightweight setup possible, the total price comes in well under $500 for a complete unit. In price comparison terms, a 3V Surefire Executive Body, Rosch SLM2, and Surefire KM1-LED competes directly with the much larger, heavier, and pricier M720V RAID system… which is too tall to be mounted at 12:00 and still lacks a front sight.

Feel, Fit, and Finish

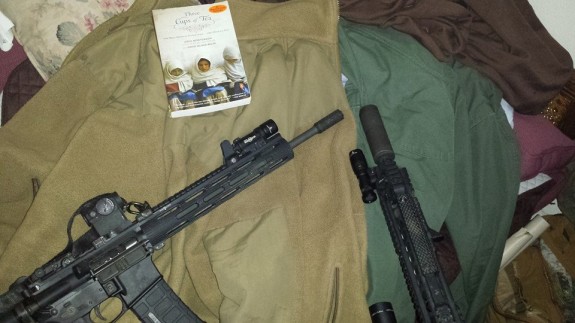

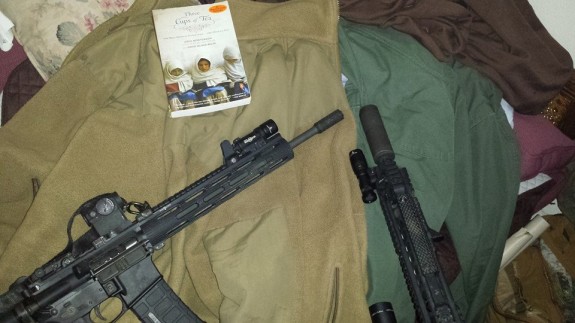

Having received a pre-production model of the SLM2, I can’t comment on the final packaging, but the remainder of the delivered setup is really quite attractive. The machine work is excellent, and on the three handguards I’ve mounted it on (KAC URX-3.1, DD RIS-II, and DD Omega-X12) the SLM slides on comfortably and tensions down solidly with no fuss. The surface under the anodize is remarkably smooth and devoid of tool marks, and any edges or corners that the user’s forward hand have the potential to interact with are neatly executed. The two rail clamp bolts use a 7/64″ hex key to tighten, and ended up just under flush with the opposite side, and actually allows small fore-aft placement adjustments for the entire SLM package before tightening the clamp screws; once tightened the solid engagement with the two screws and precise key cut clamp surfaces holds it in place securely. The ‘wing’s of the front sight to protect the post itself are concave from the inside face, with a sculpted flat outside edge – needless to say quite functional especially with the serrations continuing up the rearward angled face of them. Finally, the left side has elegantly subtle laser engraving with ROSCH Works SLM2 Made in USA markings. Arguably the best executed feature is the anti-glare serration of the angled rearward face, but it wasn’t completely without issue for me.

The only spot where I’ve had a partial issue is the lowest serration on the rearward face of the sight could be inadvertently displaced downward, or even have that section stripped away while installing the light tube into the mount. Really minor concern, and I suspect a direct result of the serration 3-D location being determined for a different diameter of flashlight tube, not to mention total non-issue once mounted (since it’s inaccessible) but there is an outside chance of displacing that bottom strip of aluminum and getting a decent cut while installing and setting up the SLM2 system – I’m still really happy to see the thoughtful and time/cost inducing sight serrations on there, which puts the SLM2 in the argument for best fixed front sight… even before the added capability of running a weaponlight through the body of the front sight.

The included front sight post (although it’s a bespoke sight post) is nearly standard width, which for myself alternating between the standard FSP type DanielDefense 1.5 Fixed Front Sights and the Knight’s Armament Co. 45° Offset Folding BUIS with it’s narrow SR-15 width FSP is actually quite usable. The post itself is a touch shorter than the standard offerings, primarily due to the flat bottom plane it sticks out of being higher because the sight base is also accommodating a flashlight tube (in this case 0.827″ Surefire E series), as well as having a slight taper towards the top – the net result is actually quite effective. The base of the post is round and threaded into the base, but there is a roughly 0.0625″ tall squared portion of the front sight post that can give purchase to a small square wrench, however a different tool (specifically a 5/64″ kex key) is actually required to make adjustments. The front sight threads vertically into the SLM base, and is held in place with a nylon ball and set screw from the right side which holds the front sight in place by tensioning the nylon lock ball into place against the threads. This arrangement allows for extremely precise height adjustments, but did present a rather amusing problem for me personally.

The SLM2 I received had the set screw tension installed at what seemed to be the maximum torque spec for the set screw (or that somebody’s idea of finger tight as recommended was a bit aggressive). The result was that the nylon ball intended to compress against the threading of the sight post wound up being compressed hard enough to lodge the ball itself in place preventing sight post rotation even after removal of the set screw – my resulting attempts to pry it loose with a paperclip wound up with me ejecting the small white nylon ball from the base onto some white carpet.

Despite my ‘brilliance’ in removal, I did miraculously find the tiny (~3.5mm) ball and was able to reinstall it. With a bit less torque applied, the sight post was still held in place brilliantly, but I was able to much more readily make front sight adjustments by simply backing off the set screw a turn and being able to rotate the front sight post with fingers instead of resorting to multitool pliers. In practice, the best option for setting the front post height is setting it to flush then making adjustments in full turn increments until a more precise solid BZO is set with fine tuned fractional rotation adjustments, then running a dab of thread locker on the set screw once it’s sorted (a tiny amount ideally, as one obviously doesn’t want some excess Loctite 242 in the threading for the sight post itself). Though Rosch Works states the threadlocker isn’t requisite for installation, I still consider this cheap assurance, especially considering the small size of the set screw and nylon ball it holds in place – same idea for the rail clamping bolts, as I don’t want them going anywhere either.

The net result from all this is that with the Z68 Tailcap and KX1 head (used by SureFire M300 Scout Light) the sight picture is remarkably uncluttered, with the front sight being quite prominent and quick to acquire as well as differentiate from the protective ‘wings’ on either side of the sight. The bezel of the weaponlight doesn’t even protrude into the sight picture, which is already an improvement over the X300 (bezel and battery door latch protrude slightly into the sight picture).

With the sight my SLM2 lives on (8″ URX3 handguard) the rear sight aperture of the Gen1 MBUS rear sight, the top-most corners of the front sight ‘wings’ end up tangent to the hazy rear sight in a correct sight alignment, which is nice – but also very sight radius and ocular distance to rear sight plane for operator dependent. In short, the SLM2 has an excellent sight picture appearance when ran with fixed or folding BUIS, and with or without a holographic sight.

Performance Testing

Testing a front sight with a relatively bulletproof flashlight still feels like the thinnest point of this review, simply because I haven’t dumped a ton of rounds down the pipe of any weapon this is mounted to, and probably lack the budget to send enough rounds to even create a problem with such a stout setup. So far the most abusive test I’ve put the SLM2 through is getting up from a magazine supported prone position while using the shade of my truck’s tailgate, idiotically catching the front corners of the front sight wings on something. Aside from adding a slightly shiny spot where I broke through the finish and dinged the aluminum, the sight is none the worse for wear – the BZO hadn’t shifted but the truck now has a decent ding on the steel bumper, so the worst part of that encounter was had by my beloved truck.

As far as actual shooting related performance notes, they’re minimal. This is actually my favorite shape/arrangement for front sights I’ve encountered – not once have I mistakenly acquired a sight alignment and sight picture with my brain mistaking a protective front sight wing for the actual front sight. Lastly, the slight taper on the front sight is yet another positive feature, albeit a minor one. When used in conjunction with a micro Aimpoint attached via lower 1/3 cowitness mount the SLM2 sits happily in the bottom half of the optic’s field of view, and using the Aimpoint Micro powered off as an oversized rear peep sight actually yielded adequate accuracy at 7yds. Ringing steel at 200yd to confirm BZO also went quite smoothly. In short, it performs as well as any fixed front sight could hope to, and considering my preference for weaponlight locations (and that every serious carbine should have a WML) if running a fixed front iron sight setup is the best option, then the SLM2 is the best option among those.

Closing Thoughts and Questions

– Who should consider buying the SL1, SLM1, or SLM2?

Anybody who wants or needs to run a 12:00 weaponlight mounting solution with a fixed front sight system, especially those with limited handguard real estate.

– Who the SLM2 is right for?

Any existing Scout Light users or shooters with a desire to mount an IR/White light ‘V’ series illuminator, or who wish to use the Scout series tailcap or SR07 remote pressure switches.

In short, any build where light weight, simplicity, and efficient use of handguard real estate is a priority, the cost for performance gained is really quite high – likely a reason why top carbine shooters like Mike Pannone seem to prefer running it.

The SL-1 complete system is still the best value and ideal answer for a pure white-light user seeking to set up an effective lightweight carbine, and the SLM1 equipped with a Surefire 6P-Fury or similar light is the best performance option for high output white lights, as well as being an excellent setup for activities like nighttime/low light hog hunting. The SLM2 really does fill a fairly small niche, but absolutely shines capability wise when compared to virtually any other weapon mounted electronics suite that provides infrared and visible spectrum illumination and laser designation when paired with things like the LDI DBAL-I2.

Disclosures

I wanted to guinea pig the Surefire Executive compatible version of the Rosch Works SLM so badly that I badgered Don into sending me one of the first models ready to be released into the wild. I did purchase the SLM2 and set of 1-cell and 2-cell light bodies at below suggested MSRP directly from Rosch Works in order to complete this review.

The SLM2 is still mounted on my personal Mk18 silhouette carbine.